| Founder(s) | Günter Fronius |

| Date of Establishment | 01st May 1945 |

| Industrial Sector | Electronics and Automation |

| Headquarter | Maharashtra |

| Presence | Global |

| Awards and Recognition | -- |

“Welding is more than just

grabbing a stick and going to work. There’s a lot of science and knowledge

involved.”

- Mike Kuehnl

After indulging myself in conversations with people

and asking them about their views on welding as a career; they expressed their

thoughts on why they don’t consider it a good career option.

The biggest misconception was, “there’s not good money

in it” followed by, “only machines are now being used for welding instead of

manpower” and that led to “doesn’t offer a lot of opportunities and there’s no

scope for it”.

Moving on to busting these myths.

Starting with not good enough income.

Welding is required in every aspect, whether it’s the production

of gadgets, electronics, cars, or airplanes.

Starting from 1,30,000 to 2,99,000 p.a rising to

8,00,000 p.a. However,

depending on experience level, the specialty, and location of

work, it’s not uncommon for welders to earn more p.a. There are a lot of

job opportunities and positions for welders to earn more, especially when it

involves numerous skill sets, such as aerospace or military or underwater

welding as well; have the potential to be even more profitable.

Welding education completes before a regular 4 to 3 years of a graduation degree, considering that welding students can finish their education and start gaining experience. As with every job, the more experience you have, the more you earn.

- There’s only use of machines and no manpower required.

Machines only work till there’s a repetitive task. Tasks involving personalization or details, or tasks requiring details. Even in situations where automated or machine tasks are being done, there is still a need for manpower regarding welding, because it’ll be more expensive and the customization and detailing of various tasks cannot be done by machines. Therefore, the requirement for manpower in welding will always be there.

- Fewer opportunities and no growth.

This misconception is quite understandable, but regardless of that, it’s still wrong. Living in India the view of men sitting in a local car shop and welding with a shield on will make anyone believe that there is no source of growth and opportunity in the welding industry, and that’s wrong. By learning different methods can open a lot of career paths. Welding jobs for projects like a bridge, a skyscraper and wouldn’t it be cool to be working on a spacecraft? As I have mentioned before welding is required in the construction, automotive, and aerospace industries opening up a lot of creative and professional opportunities and growth as well for welders.

Now, Let’s come to what welding is.

Welding is joining pieces of metals through heating or

compressing them, creating a continuum through joining the pieces. Welding is

typically applied to metals and thermoplastics, but it can also be performed

on wood. Parts joined are known as parent materials and things used to

create the form are known as consumables or fillers. An arc flame created by

the welding power source is usually the source of heat in welding. Arc welding

is the name given to arc welding, which is a type of welding that uses an arc

to create a joint. The welding heat source melts the parent metal along with

the filler to which the other metal piece is joined. Heat and pressure are

generally used to attach different metals according to their thickness and type.

While welding wood; pressure is applied to the

material followed by heat which is caused by friction.

The surfaces are prepared before applying heat and

pressure after this the materials are brought to a lower temperature.

As stated above, metals are usually welded by applying heat and pressure. It is quick as well as efficient of a method. Shielding gas safeguards the molten metal or molten pool from getting oxidized or adulterated.

There are various types of welding, but here I am going to mention the three main types of welding.

- MIG- Gas Metal Arc Welding (GMAW)

It is used in the automotive industry which consists of repairing vehicles and construction. It is a type of arc welding that requires using continuous wire known as an electrode, it also requires a shielding gas that travels through the welding heat source and prevents adulteration. It is one of the most familiar types of welding.

- STICK- Shielded Metal Arc Welding (SMAW)

It is a portable method of welding, which is usually used in construction, underwater, industrial fabrication, etc. the stick joins the metals by heating between a metal electrode that is covered and the metal parent. The stick melts along with its cover which then protects the welded metal from getting oxidized.

- TIG- Gas Tungsten Arc Welding (GTAW)

It also requires an electric arc similar to MIG. The

electrodes are of tungsten which is one of the strongest metals, it doesn’t

burn. It also requires a separate gas supply like helium or argon. This method

is used by the automotive industry as well as the aerospace industry.

After getting the misconceptions cleared and knowing

the basics of welding as a career. Here are the reasons why welding is a good

career choice.

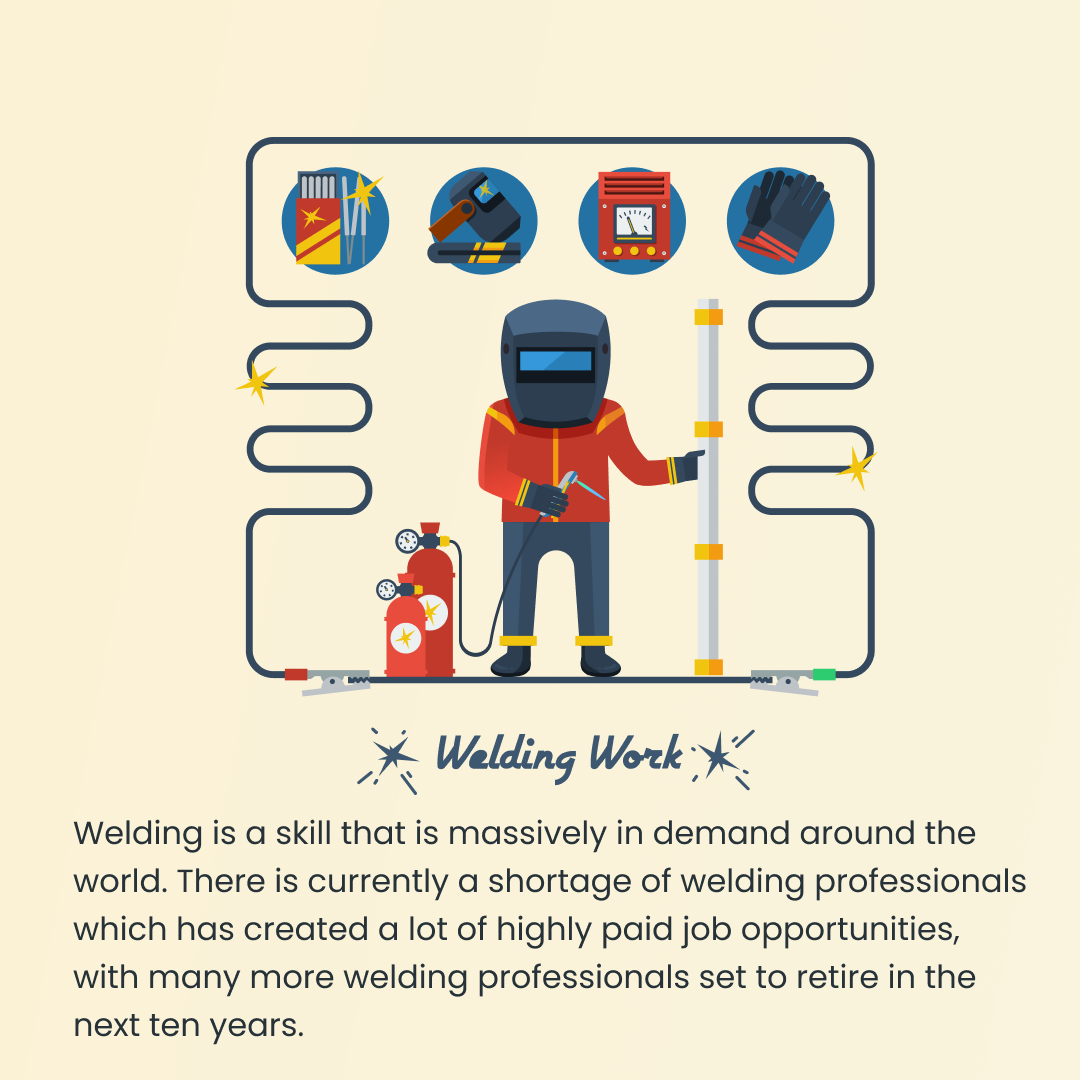

There is a great demand for welders.

In every industry almost there’s a requirement of

welders that too in every part of the world. The number of demands leads to

more work opportunities for welders and the more experience you have the higher

position and pay range you will have.

- Getting to travel and earn.

You read that right, a skilled welder is required everywhere. The welding techniques are the same everywhere. You can earn and travel as well and if you are passionate about your job and traveling, you’ll be able to work on projects you might not be able to work on locally.

- Easier to start your own business.

There is a lot of potentials to start your own company

which will yield a lot of money for you along with creating a lot more

opportunities for other welders.

If you have a desire to become an entrepreneur and have a desire of starting a company of your own, welding is a great option.

- The industry is very diverse.

There are so many different metals and materials to work with and there are so many methods to specialize in. You can work on different projects and improve your skills through each project.

- It is an enjoyable career option.

As we’ve mentioned before there are so many types of

welding and various kinds of projects to work on, it can never be boring. Welding

as a career will pay you well, there is also a shortage of professionally

skilled welders so there’s a lot of opportunities for welders to be.

Ending with something Mr. Sundarram Srinivasan

(Managing director- south Asia, Lincoln electric (I) Pvt. Ltd.) when asked: “What is your say on the future of Welding

segment in India?”

To which he said, “Welding in India has a strong future. As manufacturing grows, so will welding.”

Hopefully, this blog will help you go ahead with your

dream or consider welding as a career. Because as Temple Grandin said, “I think one of the worst things schools have done is taken out all

of the stuff like art, music, woodworking, sewing, cooking, welding, auto-shop.

All these things you can turn into careers. How can you get interested in these

careers if you don’t try them on a little bit?”.

-

-

-

-

Kala Niketan Nov 24, 2022

Kala Niketan Nov 24, 2022 -